After few months of experiences developed third anemometer minimizing

sevaral previous draw backs. This time top and bottom aluninium cubes machined

shape of cylinder.Machined steam pipe used for the middle cylinder.

After completing testing and trials middle cylinder was powder coated

by slimco staff. Placed a silica gel pack to reduce moisture condesation

inside the cylinder. Applied different color strip to each

anemometer to identify their transmitter code.

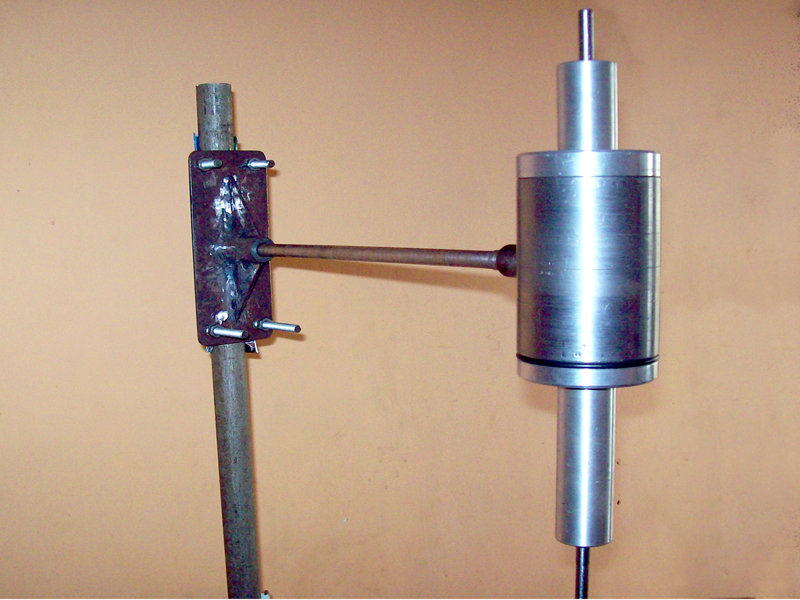

Third Anemometer

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

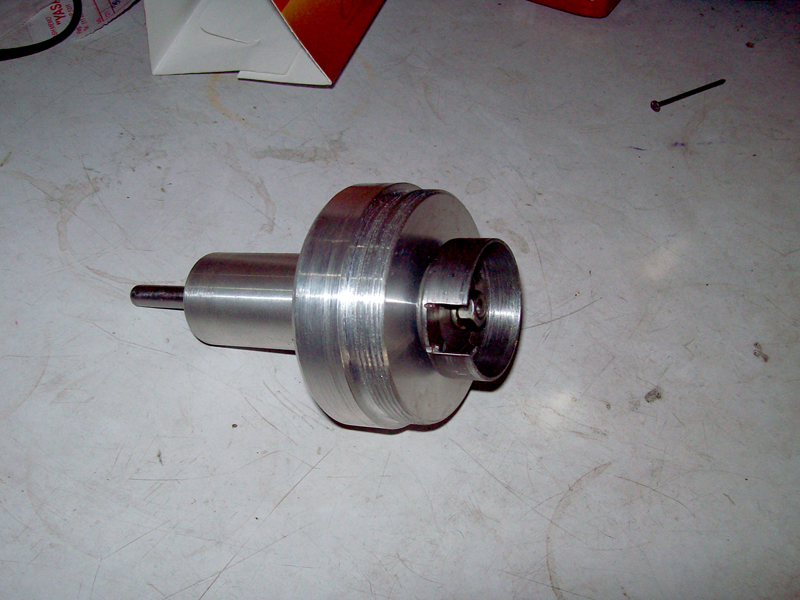

Wind Vane Solid Aluminium Lid

Figure shows slotted cup. This cup is rotating

according to wind direction in side between 8 slotted opticle switches.

same theory used for wind speed too. but used one slotted opticle switch

to measure wind speed.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

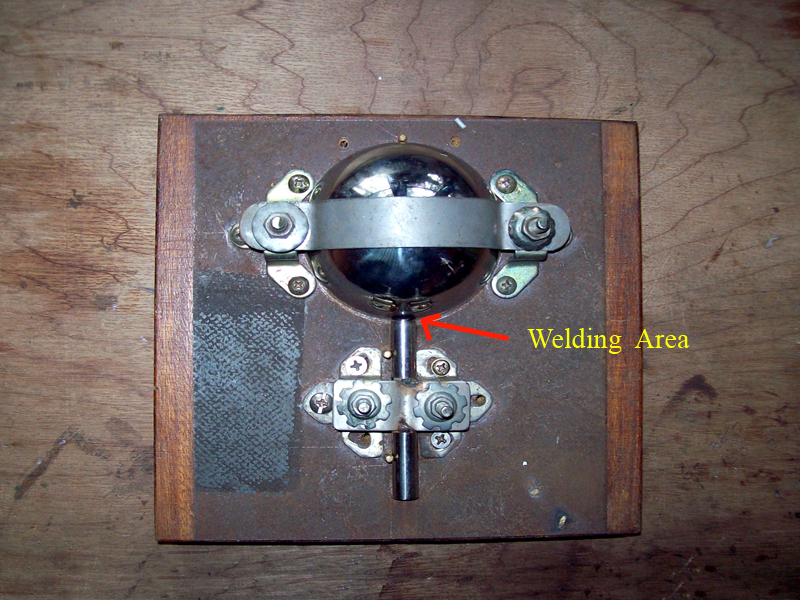

A Jig for align cup and pipe to be weld

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

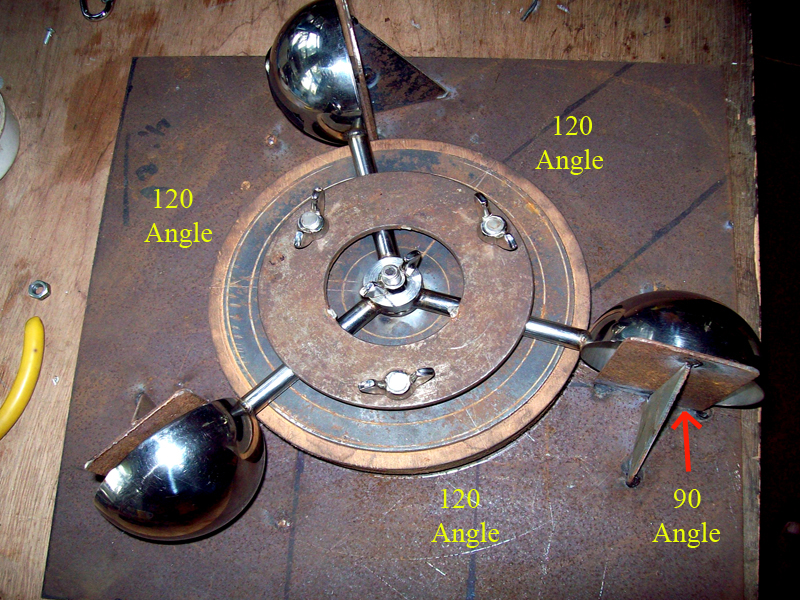

Another Jig for align all cups with pipes to weld to the center bush

Each cup and small pipes were measured identicle in size and weight.

This jig used to align all cups were verticaly in 90 Angle and 120 angle between each

cup horizontally and all cups inline horizontally.

After welding the center bush, wind cup rotor balancing was proceeded.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

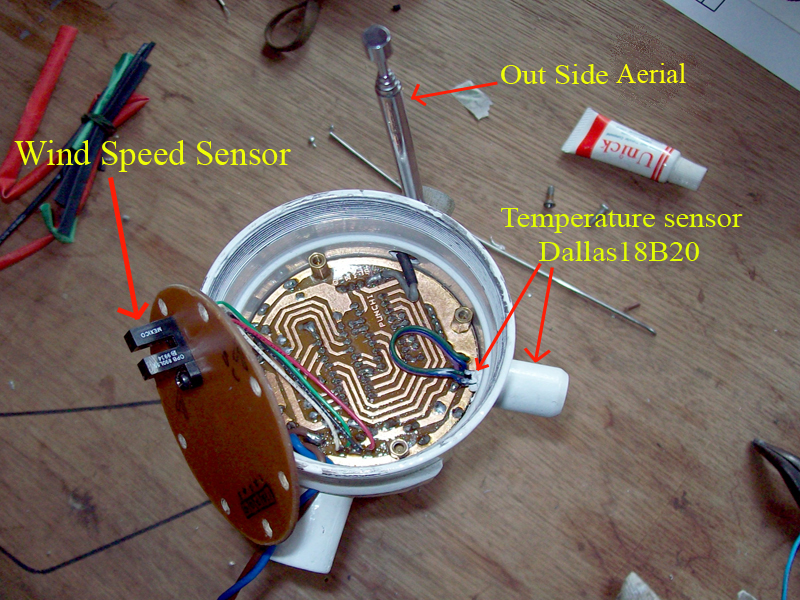

Anemometer PCBs

Three PCBS were stacked together. Top PCB contain wind

direction sensors. 8 slotted opticle sensors used, OPTEK Branded.

Middle PCB contain microcontroller, dip switch, wired Dallas18B20temperature probe,

Transmitter and some other components.Bottom Pcb contain one slotted opticle switch for

wind speed sensor.This stacked PCBs placed in the middle of cylinder.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

Anemometer inside view

All PCBs were inside the cylinder except wind speed sensor PCB.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

Two Anemometers

All Anemometers were clibrated at the work shop.

Used locally made wind tunnle to calibrate the anemometers.

After doing several calibration process at the work shop.

several site calibration process had been done.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

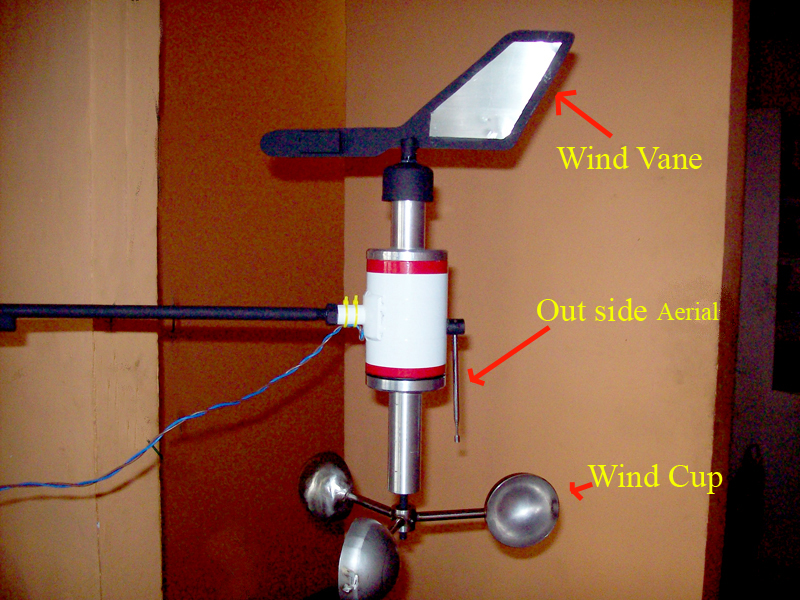

Out side Parts of the Anemometer

Wind vane used to detect the which direction wind comes from.

Telescopic Aerial( without plastic sleeve ) used to transmit the

Data ( wind direction data,wind speed data,Ambient temperature data ) to the Data logger.

Temperature probe placed oposite side of the cylinder.Not visible.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

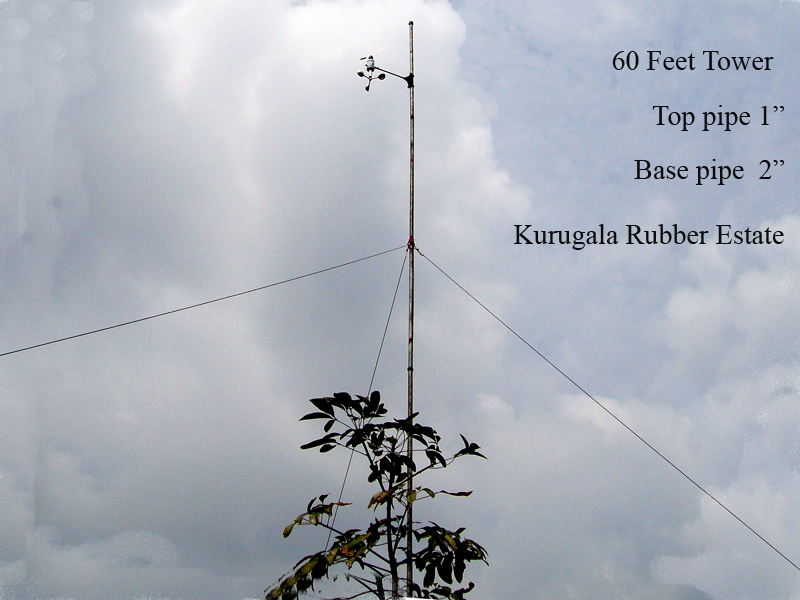

KuruGala Hill

Anemometer was installed on a top of the Kurugala Estate at

Padukka, for a Wind Survey. It was a small rubber plot,

owner of which, was interested in installing a small Wind Turbine.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

Preperations

Slimco team at the site. 60 Feet mast is being prepared.

Tower layed on the earth.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

Preperations

Tower raised 2 feet from the Ground.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

Tower Erected

Data logging started.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.

At the Site

After erecting 60 feet mast, A protection fence is being built.

Anemometer Fabricated and Installed by Slimco Eng. staff.

Location is at Kurugala Hill, Padukka.